1. Rough selection: The rough diamond needs to be carefully selected to evaluate its quality, color, clarity and cutting potential.

2. Design planning: According to the characteristics of the rough stone, experienced craftsmen will design the best cutting scheme to maximize the fire color and brightness of the diamond.

3. Preliminary segmentation: Use a laser or saw blade to divide the raw stone into small pieces suitable for further processing.

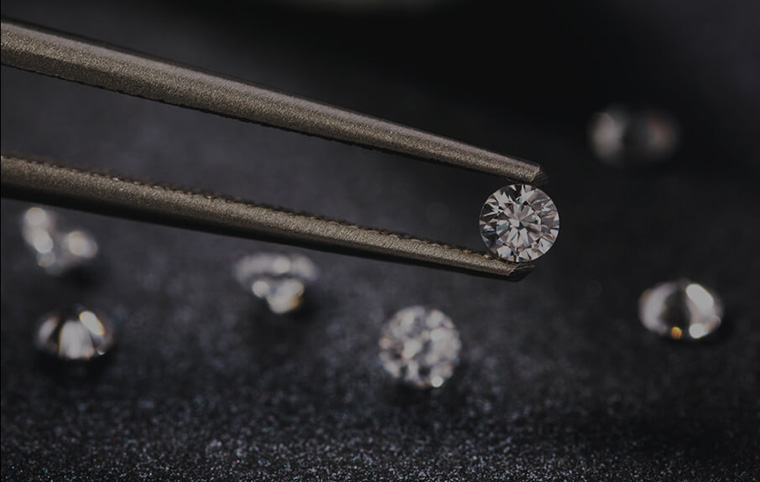

4. Shape cutting: According to the design scheme, special diamond cutting tools are used to cut different shapes.

5. Grinding and polishing: After cutting, there will be many small bumps on the surface of the diamond. The diamond needs to be polished with a grinding wheel to make its surface smooth and flat. Finally, a polishing machine is used to polish the diamond so that its surface achieves a mirror-like effect.

6. Inspection grading: After the above process, the diamond will be sent to a professional inspection agency for quality inspection and grading.

The entire process requires a high degree of expertise and precision equipment to ensure that each diamond presents its best beauty and value.